Why prevention matters

Prevention at heights is not a single control—it is a sequence: eliminate exposure where possible, install passive protection (guardrails), then add active systems (fall-arrest/restraint) where exposure remains. Procedures and training convert those controls into reliable behaviour.

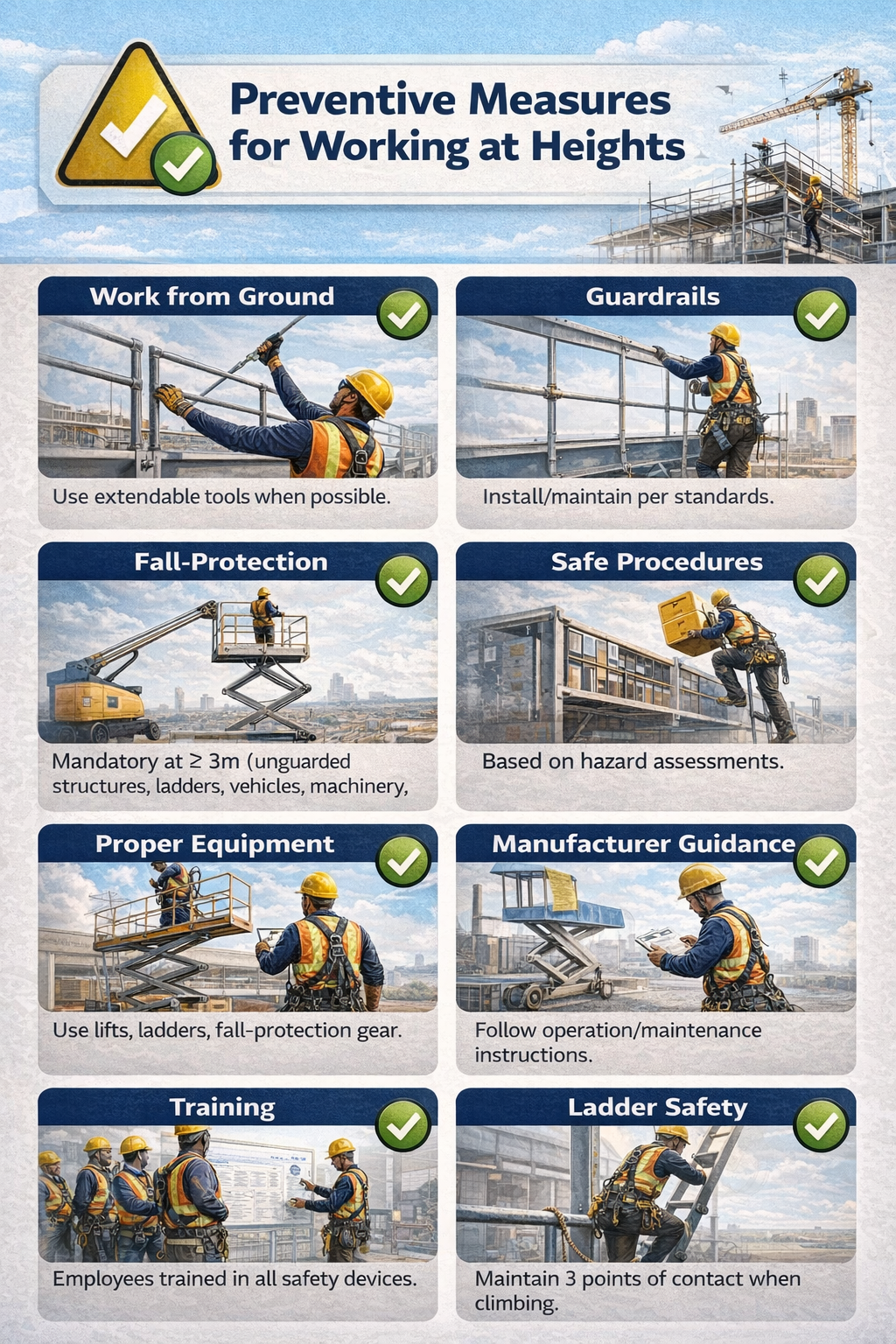

Core preventive measures

Work from ground

Use extendable tools and alternative methods to eliminate work-at-height exposure when possible.

Guardrails

Install and maintain guardrails and edge protection per applicable standards and manufacturer guidance.

Fall-protection systems

Use fall-protection when exposed to unguarded edges, ladders, vehicles, machinery, or hazardous surfaces— especially at and above typical trigger heights (often ≥ 3 m) where required by policy/regulation.

Safe procedures

Write procedures based on hazard assessments, including method statements for each work activity.

Proper equipment

Select the right access system (lifts, scaffolds, ladders) and compatible fall-protection gear for the task.

Manufacturer guidance

Follow operation and maintenance instructions (inspection intervals, anchor ratings, hardware limits).

Training

Ensure employees are trained on all safety devices and site-specific procedures before exposure.

Ladder safety

Maintain 3 points of contact, set the ladder correctly, and avoid overreaching or side loading.

Practical on-site checklist

- Confirm the task method: Can the job be completed from the ground or from a protected platform?

- Verify edge protection: Guardrails/toeboards installed, complete, and not damaged.

- Verify fall-protection plan: System type (restraint/arrest), anchor points, and rescue approach understood.

- Inspect equipment: Harness, lanyard/SRL, connectors, and anchors checked per manufacturer guidance.

- Control environment: Weather, housekeeping, access routes, and exclusion zones managed.

- Confirm competency: Worker training current and supervision available for higher-risk work.